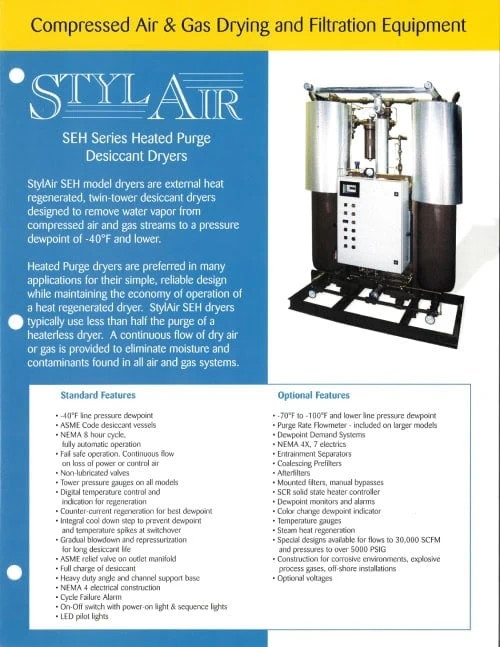

StylAir SEH model dryers are external heat regenerated, twin-tower desiccant dryers designed to remove water vapor from compressed air and gas streams to a pressure dewpoint of -40°F and lower.

Heated Purge dryers are preferred in many applications for their simple, reliable design while maintaining the economy of operation of a heat regenerated dryer. StylAir SEH dryers typically use less than half the purge of a heaterless dryer. A continuous flow of dry air or gas is provided to eliminate moisture and contaminants found in all air and gas systems.